PPGI/PPGL Sheet Coil Manufacturer

Technical Parameters

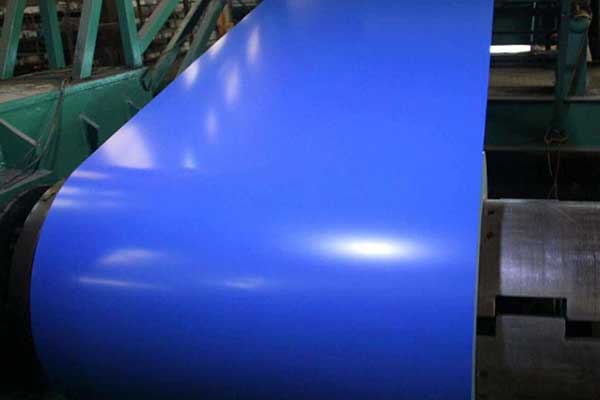

- Product Name: PPGI & PPGL Coil/Sheet, Prepainted Galvanized Steel & Prepainted Galvalume Steel, Color Coated Steel

- Standard: EN, DIN, JIS, ASTM

- Thickness: 0.12-6.00mm (±0.001mm); or customized as required

- Width: 600-1500mm (±0.06mm); or customized as required

- Zinc Coating: 20-275g/m2, or customized as required

- Substrate Type: Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel

- Surface Color: RAL series, wood grain, stone grain, matte grain, camouflage grain, marble grain, flower grain, nano, etc

- Coating Structure: PE, SMP, HDP, PVDF, PU

- Steel Grade: DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, SECE, BLCE+Z, BLDE+Z, BUSDE+Z

Shanghai AIYIA Industrial Co., Ltd. exports various PPGI & PPGL coil, such as RAL color series, wood grain pattern series, camouflage pattern series, stone pattern series, matte pattern series, flower pattern series, etc. Products are exported to the international market, and you are welcome to purchase!

Specifications of PPGI PPGL Sheet Coil

| Coil Weight | 3-20 metric ton per coil |

| Certification | ISO, SGS |

| Monthly production | 5000-10000 tons |

| MOQ(Minimum order quantity) | 20 tons |

| Delivery time | Stock: 7 days futures: 15-35 days |

| Packaging | water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by seven steel belt.or according to customer’s requirement |

| Port | Shanghai Ningbo Qingdao Qinhuangdao |

| Export market | Europe Africa Southeast Asia Middle East South America North America, etc |

Product Introduction

PPGI & PPGL (prepainted galvanized steel & prepainted galvalume steel) also known as prepainted steel or color coated steel coil, It is a product made of hot-dip galvanized steel sheet, hot-dip galvalume steel sheet, electro-galvanized steel sheet, etc. After surface pretreatment, one or more layers of organic coating are applied to the surface, and then baked and solidified.

The color coated steel coil is light in weight, beautiful in appearance, and has good anti-corrosion performance, and can be directly processed. The color is generally divided into gray, sea blue, brick red, etc. It is mainly used in advertising, construction, decoration, home appliances, electrical appliances, Furniture industry and transportation industry.

The coatings used for color coated steel coils are based on the environment in which the resin is selected, such as polyester silicon modified polyester, polyvinyl chloride plastisol, polyvinylidene chloride, and the like.

Structure Diagram of PPGI PPGL Sheet Coil

PPGI

PPGL

Production Process Diagram

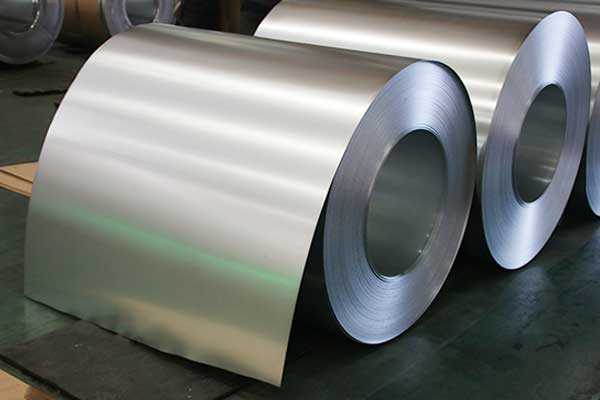

Substrate Type

Hot Dip Galvanized Steel

Hot Dip Galvalume Steel

Electro Galvanized Steel

Coating Type of PPGI & PPGL Sheet Coil

Polyester (PE)

- Good adhesion, rich colors, wide range of formability and outdoor durability, moderate chemical resistance, and low cost.

Silicon modified polyester(SMP)

- Good abrasion resistance and heat resistance, as well as good external durability and chalking resistance, gloss retention, general flexibility, and medium cost.

High Durability Polyester(HDP)

- Excellent color retention and anti-ultraviolet performance, excellent outdoor durability and anti-pulverization, good paint film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride(PVDF)

- Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good moldability, stain resistance, limited color, and high cost.

Polyurethane (PU)

- Polyurethane coating has the characteristics of high wear resistance, high corrosion resistance and high damage resistance. Under normal circumstances, the shelf life is more than 20 years. It is mainly used for buildings with severe environmental corrosion.

Main Features of PPGI & PPGL Sheet Coil

- Good durability and long life compared with galvanized steel.

- Good heat resistance, less discoloration at high temperature than galvanized steel.

- Good thermal reflectivity.

- Processability and spraying performance similar to galvanized steel.

- Good welding performance.

- Good performance-price ratio, durable performance and extremely competitive price.

PPGI & PPGL Steel Coil

Production Line

Application of PPGI & PPGL Sheet Coil

PPGI & PPGL sheets are widely used in construction, industry, household manufacturing, product packaging, interior decoration and other fields.

Product Category

Self Cleaning Prepainted Steel Coil

The self-cleaning PPGI/PPGL coils with special paint has excellent anti-staining properties, which can resist the penetration of pollutants to the coating, and also has a good self-cleaning property by rain, So it can reduce the pollution of industrial emissions, automobile exhaust, fumes, dust, as well as the cost of maintenance to the building.

Thermal Control Prepainted Steel Coil

Thermal control prepainted coil has higher near infrared reflectivity by adding special pigments and reflective wads in the paint, thereby reducing surface temperature and achieving the purpose of thermal control.

Antistatic Prepainted Steel Coil

The working principle of antistatic prepainted coil is to add some conductive materials in the insulating polyester coating, which turns the original insulating coating into a semiconductor (surface resistance 10-10’S2, the ordinary polyester coating around 10 Q2).

With the installation of construction to the ground, the accumulated static electricity on the surface of the prepainted coil, which is sourced from air convection or fabric friction, is conducted into the earthing system and then disappear, It can prevent dust and bacteria adsorption to reduce performance, prevent electricity discharge.

Antiseptic Prepainted Steel Coil

The working principle of the antiseptic prepainted coil is the addition of Ag+ to the polyester coating, which interrupts the respiration of cell bodies that invade the surface of the coating.

Hydrogen Peroxide Resistance Prepainted Steel Coil

Hydrogen peroxide (H202)is widely used because of its good sterilization effect and little harm to the environment and human body.

However, hydrogen peroxide is more corrosive to the cleaning system than other disinfectant, resulting in shorter service life of the clean enclosure system.

The working principle of Hydrogen Peroxide resistance prepainted coil is optimized by the formulation of resin system, face filler and auxiliaries in the paint, which improves the resist corrosion of hydrogen peroxide of the coating.

Animal Husbandry Prepainted Steel Coil

The animal husbandry prapainted coil is used in livest breeding, slaughtering and processing industries, which strong corrosion resistance to oxidizing disinfectant and ani waste.

With special additives in the coatings, the coating can re corrosion of acids, alkalis, disinfectants and other media at temperature and high humidity.

Why Choose Us?

Various surface coatings

A variety of color patterns are available. International high-quality paint is used. The product is resistant to corrosion and abrasion.

Output

Three PPGI & PPGL coil production lines, with a monthly output of 5000-8000 tons, meet the needs of a large number of customers, and deliver quickly.

Sales service

We have professional sales staff in Spanish, Portuguese, French, Arabic, and Russian for different markets.